HOW IT’S DONE

Stripping chocolate back to its basics, Land treats the cocoa bean with meticulous detail at

every stage of the process. This process starts with sourcing our cocoa. We work with similar minded producers such as Ingemann and Uncommon Cacao to buy the best quality cocoa whilst also providing a living income to the farmers paying 2-3 times fair trade price.

Once the cocoa has arrived in our workshop, its our job to extract the array of natural flavour which

all stems from the bean, and create enjoyment of a food in one of its purest forms...

1. SORTING

Once the cocoa beans have arrived in the workshop

first job is to hand sort them, prepping them for the

roast. This process simply involves removing spoiled

beans and any foreign materials; the odd, dead bug

stowaway who came along for the ride from the farm.

Hand sorting through endless kilos of cocoa beans

sounds time consuming...it is.

Welcome to small batch chocolate making.

2. ROASTING

A key role in unlocking the myriad of natural flavour

found in the cocoa bean can be found at the roasting

stage . Every bean variety has its own distinct

personality, so we have developed a different

roasting profile for each.

Roasting drives off volatile acids from the beans and

converts amino acids and sugars into more tasty fully

formed flavour compounds through the Maillard

reaction (browning process).

3. CRACK & WINNOW

Next step is to crack open the beans and discard the unwanted husks, which at LAND takes place on a rather primitive device.

It’s a bespoke hybrid of second-hand machines and a household hoover that successfully cracks open the beans and blows away the husks, leaving us with clean cocoa nib ready to load up into the melangeur and turn into chocolate.

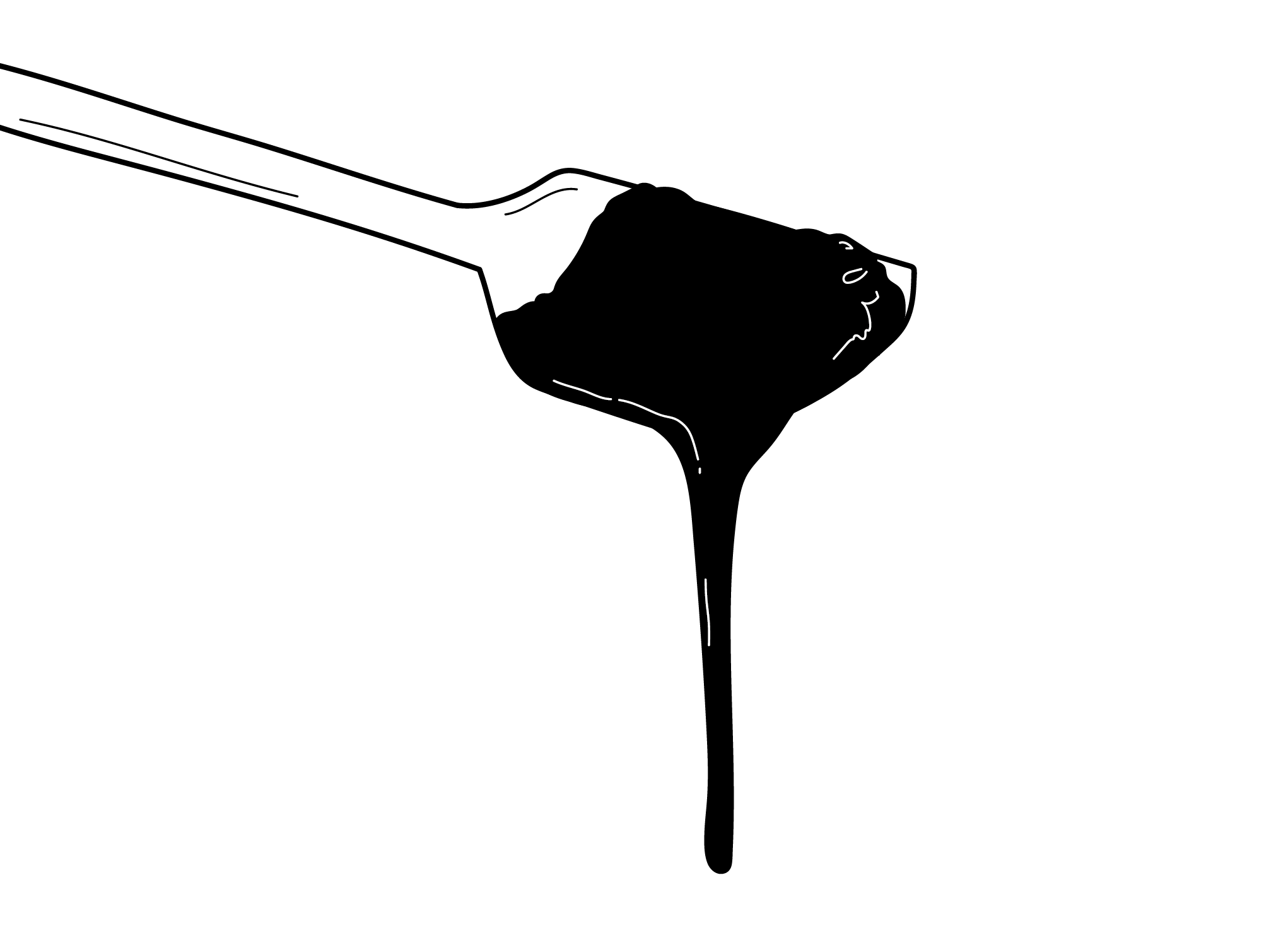

4. GRIND & CONCHE

The cocoa nibs are thrown into our stone granite

melangeur or one of our Universal grinders. These

machines break down the nibs and sugar over a 72

hour period into liquid form. By the end of the grind

particle size reduces to something between 15-20

microns, something that feels smooth on the tongue.

The chocolate is then moved onto the conching phase

where we do some final flavour development. This

involves agitating the chocolate to improve

mouthfeel, drive off any left-over volatile acids and

coax out the deeper more nuanced flavour notes.

5. TEMPER & WRAP

Tempering gives chocolate structure and is what gives

chocolate that nice shine to it. It involves heating

and cooling down the chocolate and allowing the

cocoa butter to crystallise. It’s this crystallisation

which is crucial to giving chocolate its glossy finish.

Bars are then all hand wrapped by our patient team.

A bar wrapping machine has been on the Land

Christmas list for a while… maybe next year.